- Home

- About Us

-

Products

- Coating Machineries

- VMCH (Heat Seal Lacquer) Coating Machine

- Silicon Coating Machine

- Registered Coating Cum Register Lamination Machine

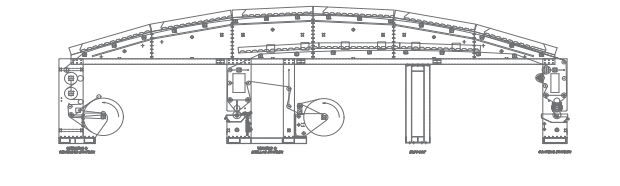

- PVDC Coating Machine

- Wax (Hotmelt) Coating Machine

- Biodegradable Water Repellent Coating-Sublimation Coating Machine

- Heat & Press Lamination Machine

- Alu Alu Lamination Machine

- Wet Lamination With On Line Coating Machine

- Solventless Lamination Machine

- Rotogravure Printing Machine For Aluminium Foil

- Flexo Printing Machine

- Surface Slitting Machine

- Giant Cantilever Slitting Machine

- 100% Inspection Machine Eagle Vision

- Hi-speed Reversible Doctoring Machine Reversible +

- Regemboss- Register Embossing Machine

- Registered Demetalization

- ELS Printing Machine

- Foil Separator Machine

- Extrusion Coating / Lamination Machine

- Investor

- Media

- Contact Us

- Packaging Unit

- E-Catalog

-

Address:

Plot No. 651,652 Village – Moti Bhoyan Taluka – Kalol Gandhinagar , Gujarat India – 382721

-

Call us 10:00am - 6:00pm

+91 9825064354 -

E-mail us

suddhaeng@yahoo.com

Application:-

V.M.C.H. Coating on Aluminium Foil, and to apply a thin coating of Shellac on Reverse Foil Surface in a Single Operation. To produce Aluminium Blister Pack and Lid Foils.

Technical Specification:-

| Materials to be processed | Hard Aluminium Foil |

| Working Width | Upto 1500 mm |

| Mechanical Speed | 100 Mpm |

| Primer Coating GSM | 0.15 – 0.50 |

| PVDC Coating GSM | 10.00- 12.00 |