- Home

- About Us

-

Products

- Coating Machineries

- VMCH (Heat Seal Lacquer) Coating Machine

- Silicon Coating Machine

- Registered Coating Cum Register Lamination Machine

- PVDC Coating Machine

- Wax (Hotmelt) Coating Machine

- Biodegradable Water Repellent Coating-Sublimation Coating Machine

- Heat & Press Lamination Machine

- Alu Alu Lamination Machine

- Wet Lamination With On Line Coating Machine

- Solventless Lamination Machine

- Rotogravure Printing Machine For Aluminium Foil

- Flexo Printing Machine

- Surface Slitting Machine

- Giant Cantilever Slitting Machine

- 100% Inspection Machine Eagle Vision

- Hi-speed Reversible Doctoring Machine Reversible +

- Regemboss- Register Embossing Machine

- Registered Demetalization

- ELS Printing Machine

- Foil Separator Machine

- Extrusion Coating / Lamination Machine

- Investor

- Media

- Contact Us

- Packaging Unit

- E-Catalog

-

Address:

Plot No. 651,652 Village – Moti Bhoyan Taluka – Kalol Gandhinagar , Gujarat India – 382721

-

Call us 10:00am - 6:00pm

+91 9825064354 -

E-mail us

suddhaeng@yahoo.com

Application:-

To coat the LDPE / PP / PLA on the paper, bord, film, foil, fabric, woven sack. Extrusion Coating and machine will be with centralized PLC control System along with integrated AC drive system & Beaks as per specifications. This Lamination machine will able to process PP/LDPE/PLA material for multiple coating applications & lamination.

Technical Specification:-

| Materials to be processed | Max Weight of Parent Roll |

| Paper, Board, Film, Pet, BOPP, Aluminium Foil, | 1000kg |

| Fabric, Woven Sack | Extruder Screw size |

| Coating Thickness | Diameter - 90mm; |

| 8 mic- 60 mic | Extruder O/P. -- 100kg/hr |

| Max Weight of Parent Roll | (subject to coating thickness, width and material used) |

| 1000 mm |

Coating process

-

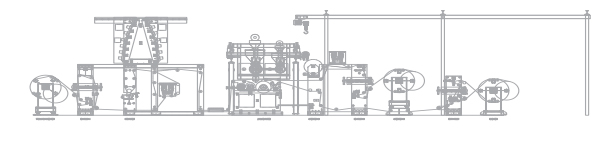

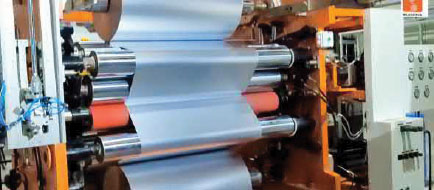

Extrusion coating and laminating unit The heart of the machine is the lamination station, which is characterized by a three-roll system with indirect pressure. The rolls, due to very precise engineering, ensure a constant temperature across the entire web, thus avoiding any stress to the material being coated - and improving the adhesion properties of the coated material to the substrate. The point of lamination is fixed giving the best web handling. Component parts of the extrusion coating and laminating unit, such as the chill roll and the pressure rolls are easily and quickly replaced and the whole group affords optimum accessibility for cleaning and maintenance. For T die deckling provision is provided.

-

cutting and connecting. This line is suitable for equipping with single extruder, multi extruders and co-extrusion. Two Station Unwinder enable fast change over of job. Optional corona treatment unit will be provided to give a treatment to the film/fabric before lamination. All Idler rollers (Diameter-100mm/) will be hard-anodized Steel/Aluminum rollers as per process requirement,