ULTIMATE SOLUTION FOR CONVERTING INDUSTRIES

Application:-

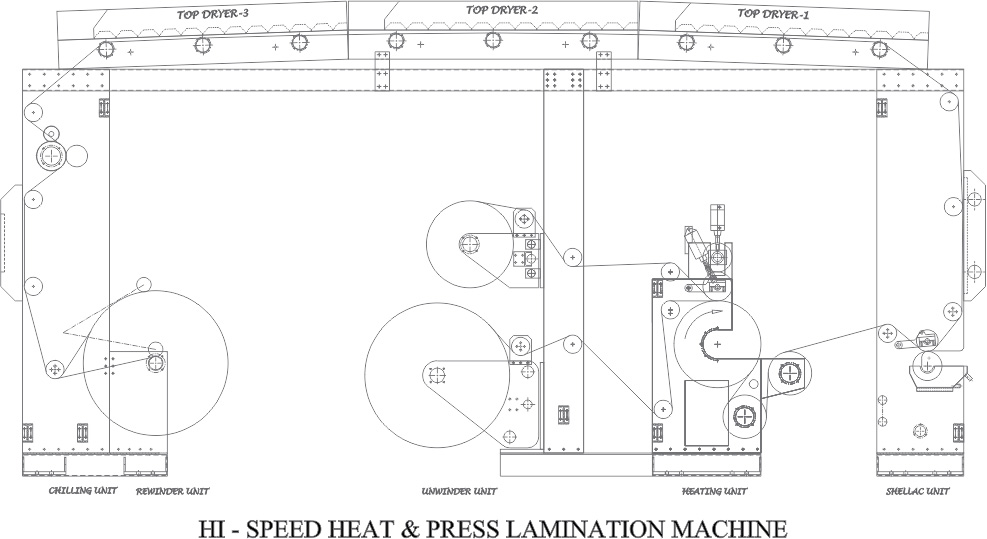

To laminate poly film with pharmaceutical grade Aluminium foil by pressure application through rubber rolls in presence of hot drum and to apply a thin coating or shellac on foil surface.Technical Specification:-

| Materials to be processed | : Aluminum Foil, Papers, PE Films |

| Maximum Working width | : 1200 mm |

| Maximum Outer Diameter | : 1000 mm |

| Maximum Mechanical Speed | : 150 Mpm |

General Specification:-

- Heating drum is driven by A.C drive system synchronized with re-winder andare dynamically balanced, ground and hard chromed.

- Pneumatic pressure application system (both side control) for both rubber rolls (hot drum & shellac wash unit)& back up roll.

- Temperature control of heating drum through submersed electric heater in thermic fluid inside drum and exit of expanded oil through rotary joint.

- Gravure coating method for shellac wash unit suitable for minimum exposed solvent area.

- Coating roller-mounting assembly can accept integral shaft type as well as hollow type coating rollers.

- High velocity drying system equipped with different zone electrical radiator based hot air dryer to dry shellac coating on foil surface.

- Passing roller inside dryer made from seem less pipe duly chromed and dynamically balanced provided proper web support against hot air.

- A separate A.C re-winder drive system synchronized with drum drive.

- Pneumatic brake un-winder tension system with load cell for poly un-winder with suitable controls.

- Pneumatic brake un-winder tension system with load cell for foil un-winder with suitable controls.

- All un-winder and re-winder are with air shaft and safety chuck mounting system suitable to adopt paper / metal core.

- Nos. of adjustable rolls are provided in different positions to compensate gauge variations of any winding defects on foil.

- A centralized material loading unloading system is there for an easy operation on the center line of the machine.

- Both of the un-windersare with manual guiding system with liner motion bearing based travelling trolley

Get in touch

You will find yourself working in a true partnership that results in an incredible experience, and an end product that is the best.

Call us on

+91 9825064354

+91 7211145364

+91 7203095730

Email us

suddhaeng@yahoo.com

sales@suddhagroup.com